Global tyre manufacturer Kumho Tyres has announced that it has launched a new tyre digital twin system at its global headquarters in Seoul, marking a major step in the company’s efforts to digitalise its tyre development process.

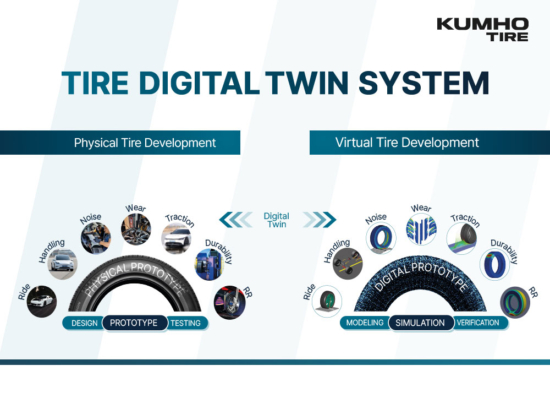

Shifting from traditional physical testing to virtual tyre development, Kumho says the new system enables the automatic design of multiple tyre versions using digital data and big data-based performance predictions.

Kumho says its Digital Twin system shifts tyre development from traditional physical methods to a dynamic virtual environment and comes in response to the growing demand for digital transformation among automakers along with stricter environmental regulations.

This allows design engineers to generate tyre designs, predict performance, optimise designs, and simulate vehicle performance - all within a digital framework.

Using artificial intelligence (AI), the system selects the optimal design, and follows this up with a virtual evaluation based on vehicle dynamics analysis to verify tyre performance.

“Tyres must meet strict standards for rolling resistance, braking, wear, comfort and noise reduction,” said the head of Kumho Tyre’s Virtual Product Development Centre Kim Keewoon.

“Emphasising the need to optimise key design factors like compounds, tread patterns, structure and shape for more efficient testing and improvement of these elements,” he added.

Kumho Tyre expects to shorten development timelines, improve performance and reduce costs with this system.

Kim Keewoon elaborated on the company’s strategy, saying that it would incorporate new technologies such as computer aided engineering (CAE), artificial intelligence and digital transformation into the tyre development process.

“The digital twin system will enhance our technological competitiveness and support the development of more advanced, higher-performance tires,” said Kim.

Kumho Tyre says it plans to evolve its digital twin system into a cloud-based platform, enabling tyre designers to work seamlessly from any location on the planet.

Kumho Tyre says the system is poised to shorten development timelines, enhance tyre performance, and reduce overall costs, furthering its leadership position in the future of tyre technology, with these innovations.

The company also aims to enhance its performance prediction systems using big data analytics and introduce driving simulators integrated with vehicle dynamics analysis.

The cutting-edge system is aimed at accelerating tyre development in an increasingly complex automotive landscape.

"We are excited to apply state-of-the-art technologies like CAE, artificial intelligence, and digital transformation to our tire development process," said Kim.

"The Digital Twin system will enhance our competitive edge, enabling us to develop more advanced tyres that deliver superior performance more quickly."

This global accessibility will ensure that teams can collaborate seamlessly allowing ongoing upgrades to the performance prediction system that will continuously enhance the reliability and accuracy of tyre performance assessments, while advanced vehicle simulators will improve vehicle dynamics predictions.

Kumho Tyre, is one of the world’s largest tyre manufacturers, with more than 60 years of history of pioneering innovative approaches to developing tyres and is dedicated to providing exceptional driving experiences to consumers around the world.